Crystallization Definition Techniques Process and Examples

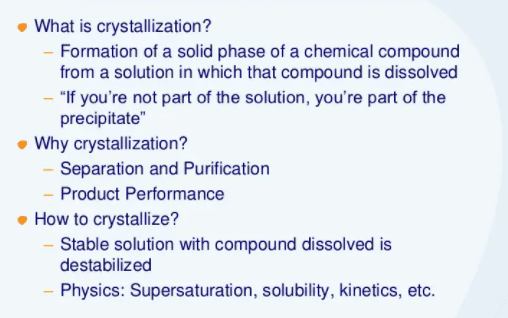

What is Crystallization – Definition

Crystallization is the removal of a solid from a solution by increasing its concentration above the saturation point in such a manner that the excess solid separates out in the form of crystals.

in such a manner that the excess solid separates out in the form of crystals.

The preparation of a chemical compound usually affords a crude product and there is a need to purify it by crystallization from a suitable solvent. The basic principle of crystallization is the fact that the solute should be soluble in a suitable solvent at high temperature and the excess amount of the solute is thrown out as crystals when it is cooled. The process of crystallization involves the following steps.

Choice of a solvent

The solvent is chosen on a hit and trial basis and it is necessary to try a number of solvents before arriving at a conclusion. An ideal solvent should have the following features.

- It should dissolve a large amount of the substance at its boiling point and only a small amount at room temperature.

- It should not react chemically with the solute.

- It should either not dissolve the impurities or the impurities should not crystallize from it along with the solute.

- On cooling, it should deposit well-formed crystals of the pure compound.

- It should be inexpensive.

- It should be safe to use and should be easily removable.

The solvents which are mostly used for crystallization are water, rectified spirit (95% ethanol), absolute ethanol, diethyl ether, acetone, chloroform, carbon tetrachloride, acetic acid, and petroleum ether. If non of the solvents is found suitable for crystallization, a combination of two or more miscible solvents may be employed. If the solvent is inflammable then precaution should be taken while heating the solution so that it does not catch fire. In such cases, the water bath is used for heating purposes.

Preparation of the saturated solution

After selecting a suitable solvent, the substance is then dissolved in a minimum amount of solvent and is heated directly or on a water bath with constant stirring. Add more solvent to the boiling solution if necessary until all the solute has dissolved.

Filtration

The insoluble impurities in the saturated solution are then removed by filtering the hot saturated solution, through a normal or fluted filter paper. This avoids the premature crystallization of the solute on the filter paper or in the funnel stem. If necessary hot water funnel should be used for this purpose.

Cooling

The hot filtered solution is then cooled at a moderate rate so that medium-sized crystals are formed. Slow cooling yields bigger crystals which are likely to include a considerable amount of solvent carrying impurities with it and complicating the drying process.

Collecting the crystals

When the crystallization is complete, the mixture of crystals and the mother liquor is filtered through a Gooch crucible using a vacuum pump. Full suction is applied in order to drain the mother-liquor from the crystals as effectively as possible. When the filter cake is rigid enough it is pressed firmly with a cork to drain the leftover liquid.

The crystals are then washed with a small portion of cold solvent and the process is repeated several times. The mother liquor is quite often concentrated by evaporation and cooled to obtain a fresh crop of crystals. The process of crystallization appears to be very simple yet the success of operation lies in the amount or the percentage of the crystallized product obtained from the crude substance.

Drying of the crystallized substance

Pressing it between several folds of filter papers and repeating the process several times dries the crystallized substance. This process has the disadvantage that the crystals are crushed to a fine powder and sometimes the fibers of filter paper contaminate the product. Alternatively, the crystals are dried in an oven provided the substance does not melt or decompose on heating at 100˚C.

A safe and reliable method of drying crystals through a vacuum desiccator. In this process, the crystals are spread over a washed glass and kept in a vacuum desiccator for several hours. The drying agents used in a desiccator are CaCl2, silica gel, or phosphorus pentaoxide.

Decolourization of undesirable colors

Sometimes during the preparation of a crude substance, the coloring matter or resinous products affect the appearance of the product and it may appear colored. Such impurities are conveniently removed by boiling the substance in the solvent with a sufficient quantity of finely powdered animal charcoal and then filtering the hot solution. The colored impurities are absorbed by animal charcoal and the pure decolorized substance crystallizes out from the filtrate on cooling.

Sublimation

It is a process in which a solid, when heated, vaporizes directly without passing through the liquid phase and these vapors can be condensed to form the solid again. It is frequently used to purify a solid. Examples of such solids are ammonium chloride, iodine, naphthalene, benzoic acid, etc. To carry out the process, the substance is taken in a watch-glass covered with an inverted funnel. The substance is then heated slowly over a stand bath and the funnel is cooled with wet cotton. The pure solid deposits on the inner side of the funnel.

You May Also Like: